Key Takeaways

- Always turn off power at the circuit breaker before attempting any electrical wire repairs

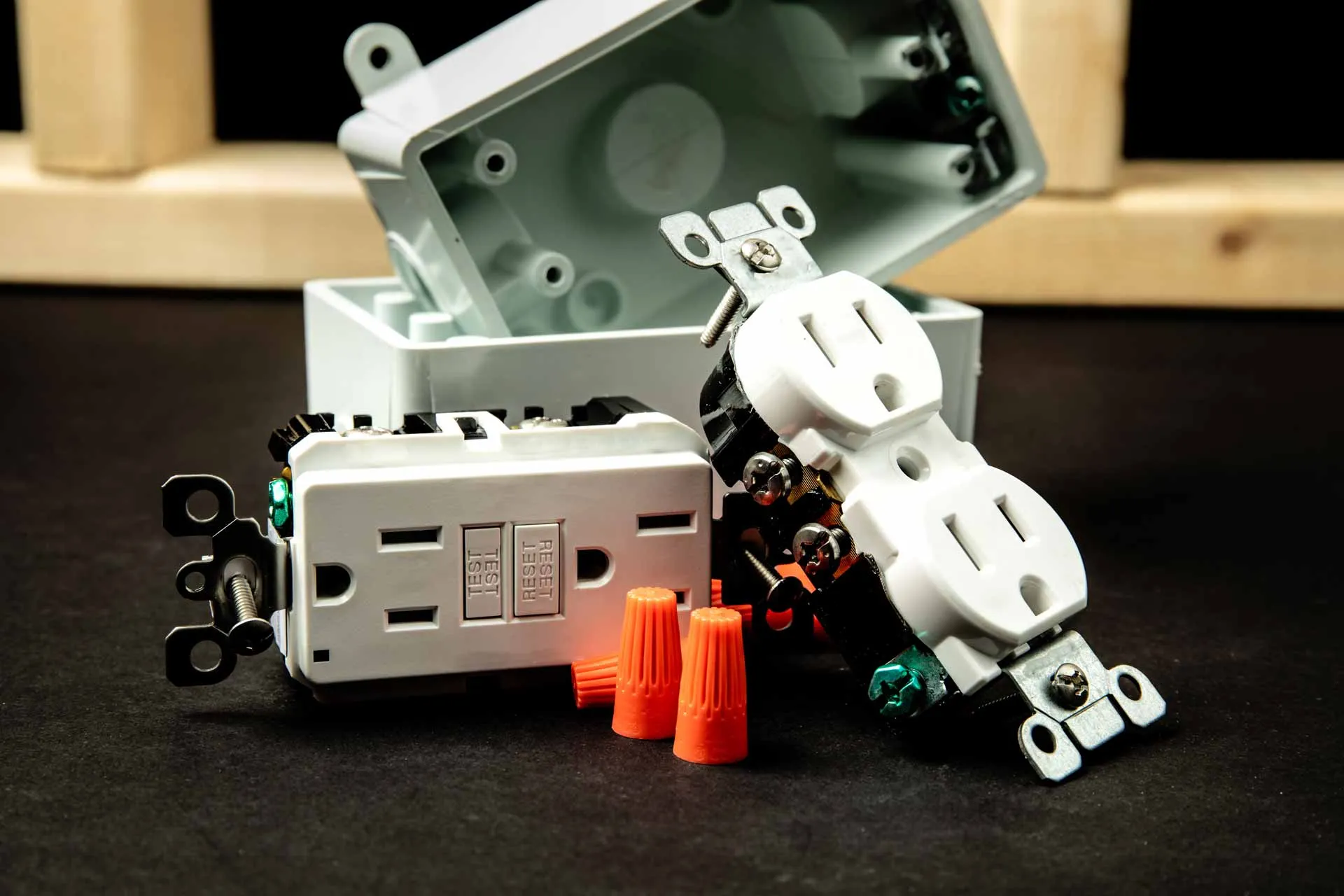

- GFCI outlets are essential safety features for kitchens, bathrooms, and other wet areas

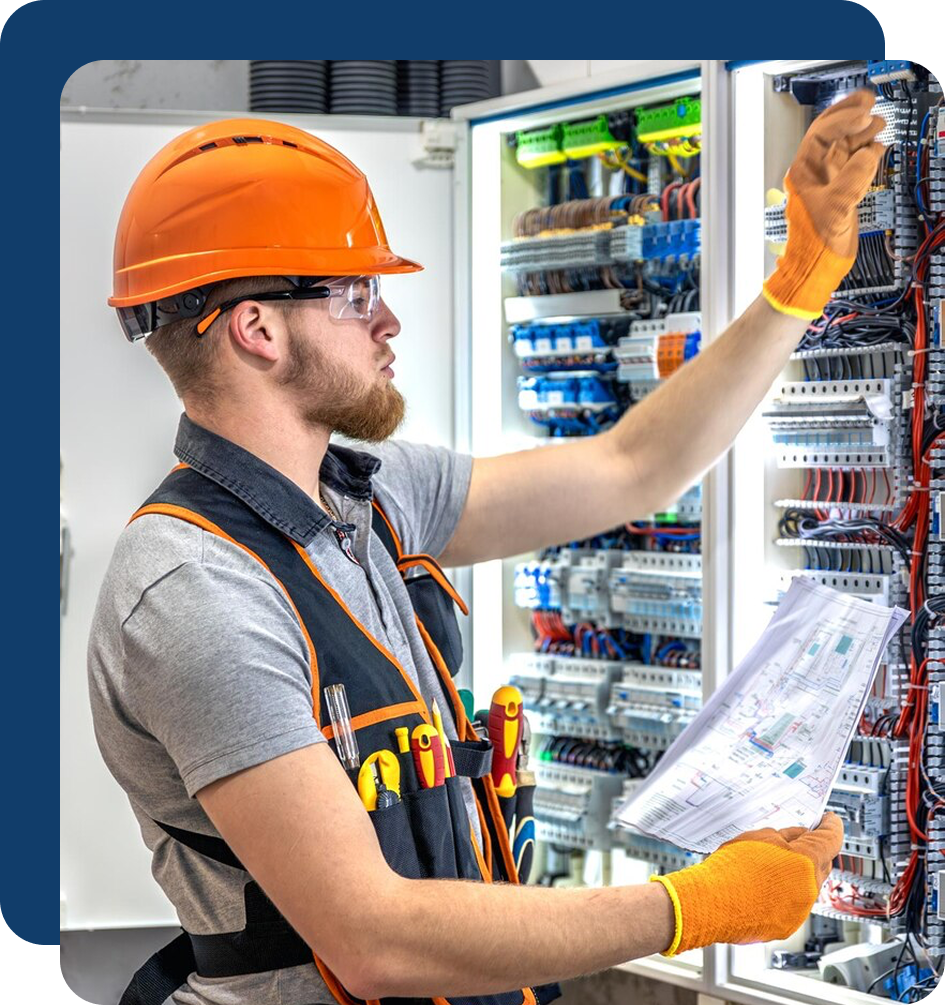

- Professional electricians should handle complex electrical issues to ensure safety and code compliance

- Regular electrical inspections can identify potential hazards before they become emergencies

- Surge protectors are crucial for protecting valuable electronics from power surges

- Consider an electrical panel upgrade if you experience frequent circuit breaker trips

- Outdated wiring in older homes may not support modern electrical demands

- Physical damage to wires from rodents or renovation work is a common cause of electrical issues

- LED lighting reduces strain on your electrical system while improving energy efficiency

- Proper use of electrical outlets prevents overloading and reduces fire risks

Electrical wire damage is a serious issue that affects thousands of homes each year. According to the Electrical Safety Foundation International, home electrical fires account for an estimated 51,000 fires annually, resulting in nearly 500 deaths, more than 1,400 injuries, and $1.3 billion in property damage. Understanding how to identify, prevent, and properly repair electrical wire issues is essential for every homeowner. This comprehensive guide will walk you through everything you need to know about electrical wire repair, from recognizing potential hazards to knowing when to call a professional.

Recognizing Wire Damage and Electrical Hazards

Electrical wire damage is a common issue in many homes, particularly in older properties where wiring systems may be outdated or deteriorating. Damaged electrical wires pose significant safety risks including electrical fires, shocks, and power outages. At Estevez Electric LLC, we put safety first when dealing with electrical wire repairs.

Before attempting any electrical work, it’s crucial to understand the potential hazards. Faulty wiring is among the leading causes of residential fires in the United States. Signs of damaged wires include flickering lights, burning smells, discolored outlets, and frequent circuit breaker trips. These symptoms should never be ignored as they could indicate serious underlying issues that might become dangerous situations if left unaddressed. The Consumer Product Safety Commission reports that electrical failures or malfunctions contribute to nearly 50,000 home fires each year, highlighting the importance of proper wire maintenance and repair.

When you have an electrical emergency, you need professional help right away. Trying to fix complex electrical problems without proper training can cause injuries or make the problem worse. Our team of licensed electricians has the knowledge and tools to safely fix all types of wire damage, from simple frayed insulation to complex wiring system failures that need lots of troubleshooting and repair work.

Older homes often have more electrical hazards because their wiring systems weren’t made to handle today’s electrical needs. If your home is more than 30 years old, you should get a complete electrical inspection to find potential problems before they become dangerous. Many older homes still have aluminum wiring or knob-and-tube systems that don’t meet current safety standards and may cause fires when connected to modern appliances and electronics that use more power than these systems were designed to handle.

Common Causes of Electrical Wire Damage

Electrical wire damage can occur due to various factors, and understanding these causes can help homeowners take preventive measures. Let’s explore the most common reasons for electrical wire damage in residential properties.

Physical Damage and Wear

Physical damage is one of the most common causes of electrical wire issues. This includes wires that have been pinched, cut, or punctured during home renovations or furniture movement. Rodents can also chew through wire insulation, exposing the conductive material and creating fire hazards. Regular inspections of visible wiring, especially in attics, basements, and crawl spaces, can help identify such damage early.

Over time, normal wear and tear can also degrade wire insulation, particularly in areas exposed to environmental stressors like heat, humidity, or UV radiation. Wires running through uninsulated attics or near heating appliances are especially vulnerable to breaking down too soon. Professional electricians recommend checking exposed wiring at least once a year to catch degradation before it leads to dangerous shorts or electrical fires.

Overloaded Circuits

Circuit overloads happen when too many devices draw power from a single circuit, exceeding its capacity. This is especially common in older homes that weren’t designed to handle multiple modern appliances. Signs of an overloaded circuit include frequent breaker trips, dimming lights when appliances turn on, and warm outlets or switch plates. Upgrading your electrical panel can provide the additional capacity needed for today’s electrical demands.

When circuits are constantly overloaded, the extra current flowing through the wires creates heat that can gradually damage insulation and even melt the copper conductors inside. This not only creates immediate fire hazards but also damages the entire wiring system over time, leading to more frequent failures and potentially dangerous situations. The National Fire Protection Association estimates that overloaded circuits cause about 7,400 home fires each year in the United States, making proper load management essential for electrical safety.

Water Damage and Moisture Exposure

Water and electricity are a dangerous combination. Moisture can seep into outlets, junction boxes, or wire insulation, causing corrosion and creating short circuits. This is why GFCI outlets are essential in bathrooms, kitchens, and outdoor areas where water exposure is likely. These special outlets can detect ground faults and quickly cut power to prevent shocks.

Even small water problems, like condensation in humid places or minor roof leaks, can badly damage electrical systems over time. Water-damaged wiring might work at first while corrosion slowly develops at connection points and inside the wires themselves. This hidden damage can eventually cause electrical failures, arcing, and increased fire risks. According to electrical safety experts, water damage to electrical systems is particularly tricky because the damage often gets worse without being noticed until something catastrophic happens.

Power Surges

Power surges can damage electrical wiring and connected devices. These surges may be caused by lightning strikes, utility company issues, or the cycling on and off of large appliances. Installing whole-house surge protectors provides an essential layer of protection for your home’s electrical system and valuable electronics.

While most people think power surges come from lightning strikes, actually up to 80% of damaging power surges start inside the home. When large appliances like air conditioners, refrigerators, or washing machines turn on and off, they can create mini-surges that slowly damage wiring insulation and electronic components over time. These repeated small surges can be just as harmful as a single large event, causing damage that shortens the life of both your wiring and connected devices. Professional-grade surge protection systems offer multiple layers of defense against both external and internal surge sources.

Safety Precautions Before Attempting Wire Repairs

Safety should always be the top priority when dealing with electrical systems. Before attempting any wire repairs, even minor ones, certain precautions must be taken to prevent electrical shocks, fires, or other hazards.

Turn Off Power at the Source

The most important safety step is to shut off power to the circuit you’ll be working on. This means finding your home’s electrical panel and turning off the right circuit breaker. Never rely only on wall switches to cut power, as they only disconnect one side of the circuit.

It’s important to know that modern homes usually have multiple circuits, and finding the correct breaker is essential for safety. Many homeowners make the dangerous mistake of turning off what they think is the correct breaker without properly checking. Always test multiple outlets or fixtures on the same circuit to make sure power is completely disconnected. For extra safety, some professional electricians suggest putting bright tape or a note on the breaker panel while work is being done to prevent someone else from accidentally turning the power back on during repairs.

Verify Power is Off

After turning off the circuit breaker, always verify that power is indeed off before touching any wires. Use a non-contact voltage tester to check all wires you’ll be working with. This simple tool can detect electrical current without making direct contact with the wire, providing an additional layer of safety.

Non-contact voltage testers detect the electromagnetic field around energized conductors. They provide an essential second check that can prevent potentially fatal mistakes. According to electrical safety statistics, a significant percentage of electrical injuries happen when people incorrectly assume circuits are turned off. For complete safety, test both the black (hot) and white (neutral) wires, as well as any metal parts that might be energized. Remember that some electrical faults can energize parts of a system in unexpected ways, making thorough testing critical before starting any repair work.

Use Proper Tools and Equipment

Working with electrical systems requires specialized tools designed for electrical work. These include insulated screwdrivers, wire strippers, needle-nose pliers, and electrical tape. Using the right tools not only makes the job easier but also enhances safety. At Estevez Electric LLC, our technicians use professional-grade equipment to ensure the highest safety standards.

Insulated tools are specially designed with non-conductive handles and protective coatings that can withstand up to 1,000 volts, providing crucial protection against electrical shock. The International Electrotechnical Commission (IEC) has established standards for insulated tools, requiring them to undergo strict testing to ensure they can safely withstand voltage spikes and prevent current from reaching the user. Professional electricians regularly check their tools for damage to the insulation, as even small nicks or cracks can compromise safety. For homeowners attempting minor electrical repairs, investing in properly rated insulated tools is an essential safety precaution that should never be skipped.

Know When to Call a Professional

While some minor electrical repairs can be handled by homeowners with basic knowledge, many situations require professional expertise. Complex wiring issues, electrical panel work, or any repair that makes you uncomfortable should be left to licensed electricians. Remember, the cost of professional service is minimal compared to the potential risks of improper repairs.

According to the Electrical Safety Foundation International, DIY electrical projects cause nearly 400 electrocution deaths and thousands of injuries annually in the United States. Professional electricians go through extensive training and certification, typically completing 4-5 year apprenticeship programs and getting thousands of hours of supervised experience before becoming licensed. They understand complex electrical codes that vary by location and are continuously updated as safety standards evolve. When dealing with issues like aluminum wiring, knob-and-tube systems, or service panel upgrades, professional expertise isn’t just convenient—it’s essential for ensuring your home meets current safety standards and insurance requirements.

Essential Tools for Electrical Wire Repair

Having the right tools is crucial for safe and effective electrical wire repairs. While professional electricians have extensive toolkits, homeowners should have these basic tools for minor electrical work and emergencies.

Basic Electrical Testing Tools

A non-contact voltage tester is essential for verifying that power is off before beginning any electrical work. A multimeter provides more detailed information about voltage, current, and resistance in your electrical circuits. These testing tools help identify problems and ensure safety during repairs.

Modern digital multimeters have features like auto-ranging capabilities that automatically select the appropriate measurement range, making them more user-friendly for homeowners with limited electrical experience. When troubleshooting electrical issues, a multimeter can help determine whether a problem is with the power source, the wiring, or the connected device. For example, measuring voltage at an outlet can confirm whether power is reaching that point in the circuit, while resistance measurements can identify broken conductors or faulty connections that might not be visible. Investing in quality testing equipment is particularly important, as inaccurate readings from low-quality devices can lead to dangerous misdiagnoses of electrical problems.

Wire Cutting and Stripping Tools

Quality wire cutters and strippers are essential for preparing wires for connections. These tools allow you to remove insulation without damaging the conductor inside. For more complex work, a cable ripper can help remove the outer sheathing of multi-conductor cables safely.

Professional-grade wire strippers have precisely sized openings for different wire gauges, allowing clean insulation removal without damaging the copper conductors. This precision is crucial because even minor damage to conductors can create resistance points that generate heat and potentially lead to connection failures over time. Automatic wire strippers with adjustable depth settings can further improve accuracy and efficiency, especially when working with many connections. For specialized applications like low-voltage wiring in smart home systems, dedicated precision strippers designed for smaller gauge wires may be necessary to prevent damage to delicate conductors that carry data signals rather than power.

Connection and Insulation Materials

Wire connectors (wire nuts), electrical tape, and heat shrink tubing are essential for making secure connections and providing proper insulation. For more permanent repairs, professional installation of outlets and junction boxes may be necessary.

Modern wire connectors have improved a lot from basic wire nuts to include push-in connectors and lever-lock systems that create more reliable connections without needing twisting or taping. These advanced connectors often have clear housings that let you see if the wire is properly inserted and connected. Heat shrink tubing provides better insulation than electrical tape because it creates a waterproof seal that won’t unwrap or break down over time. Available in different sizes and colors for circuit identification, heat shrink tubing can be very useful in damp locations or outdoor applications where moisture resistance is important. For critical connections, professional electricians often use special waterproof wire connectors with built-in sealant that creates a permanent moisture barrier.

Step-by-Step Guide to Basic Wire Repair

While complex electrical issues should be handled by professionals, some basic wire repairs can be performed by homeowners with proper knowledge and precautions. Here’s a step-by-step guide for simple wire repairs.

Identifying the Problem

Before attempting any repair, identify the specific issue with the wire. Is it a cut, frayed insulation, or a loose connection? Understanding the problem will help determine the appropriate repair method. Look for visible damage, but also check for signs like intermittent power, flickering lights, or unusual sounds.

When investigating electrical issues, use all your senses to gather information. A burning smell often means overheating parts or insulation, while buzzing or crackling sounds may indicate arcing electricity. Discoloration around outlets or switches usually shows heat damage from loose connections or overloaded circuits. For problems that come and go, think about environmental factors that might happen at the same time—do lights flicker when certain appliances run, or do problems get worse during rainy weather? Systematic troubleshooting involves isolating variables by disconnecting devices one by one to find the source of the problem. Write down what you find carefully, as patterns of electrical behavior can provide valuable diagnostic information to professional electricians if you eventually need to call for help.

Preparing the Wire

After turning off power and verifying it’s off with a voltage tester, prepare the damaged wire for repair. For a cut wire, strip about 3/4 inch of insulation from each end using wire strippers. Be careful not to nick the copper conductor, as this could create a weak point in the wire.

The exact amount of insulation to remove depends on the connection method and wire gauge. For standard wire nuts, 3/4 inch is usually appropriate for residential wiring, but specialized connectors may require different preparation. When working with stranded wire, take extra care to ensure all strands are captured in the connection—even a few loose strands can create potential hazards or connection failures. After stripping, inspect the exposed conductor carefully under good lighting to verify there are no nicks or damage. Twisted or bent conductors should be straightened gently before connection to ensure maximum contact surface area. For aluminum wiring, which is still present in many older homes, special preparation techniques and compatible connectors are essential, as aluminum expands and contracts at different rates than copper, potentially leading to loose connections over time.

Making Secure Connections

For simple wire splices, twist the stripped ends together in a clockwise direction. Then secure the connection with an appropriately sized wire nut, turning it clockwise until tight. For added protection, wrap the connection with electrical tape. For more permanent repairs, consider professional installation services.

The National Electrical Code (NEC) requires that all electrical connections be both mechanically and electrically secure. This means connections must physically hold together even under tension and provide consistent electrical conductivity without creating resistance. Pre-twisting wires before applying wire nuts is a best practice that creates a more reliable connection, though some newer wire connectors are designed to work without pre-twisting. When selecting wire nuts, color coding indicates the size range they accommodate—using the wrong size can result in loose connections that generate heat. For critical connections or those in damp locations, consider using gel-filled waterproof wire connectors that provide environmental protection. Remember that all spliced connections must be contained within an accessible junction box—concealed splices within walls violate electrical codes and create significant fire hazards.

Testing the Repair

After completing the repair, restore power to the circuit and test the repaired wire to ensure it’s functioning properly. Look for any signs of problems like sparking, unusual sounds, or heating. If any issues occur, immediately turn off power and consult a professional electrician.

Effective testing goes beyond simply checking that power has been restored. For thorough testing, monitor the repaired connection under load conditions by running the devices or appliances it serves at their maximum typical capacity. This stress testing can reveal issues that might not be apparent under minimal load. Using an infrared thermometer to check for abnormal heating at connection points can identify potential problems before they become dangerous. For critical repairs, consider checking again after 24 hours, one week, and one month to ensure the repair remains stable over time. Some professional electricians use thermal imaging cameras to identify hot spots that might indicate resistance problems in connections that aren’t visible to the naked eye. Remember that even successful DIY repairs should be documented in your home maintenance records, noting the date, specific work performed, and materials used.

Professional Wire Repair Services

While some minor electrical repairs can be handled by homeowners, many situations require professional expertise. Here’s when and why you should consider professional wire repair services.

When to Call a Professional Electrician

You should call a professional electrician for:

- Complex wiring issues

- Repairs inside walls or ceilings

- Electrical panel work

- Persistent electrical problems

- Any repair you’re not comfortable performing yourself

- Installation of new outlets or fixtures

- Upgrading circuits for high-power appliances

- Troubleshooting intermittent electrical issues

- Any work requiring permits or inspections

Benefits of Professional Electrical Services

Professional electricians bring several advantages to wire repair projects:

They have expertise and specialized training in electrical systems. They know electrical codes and safety standards that keep your home safe. They have the right tools and equipment for any job. Their work comes with a warranty for your peace of mind. They provide complete solutions that fix the root cause, not just the symptoms. They carry insurance that covers potential damages during work. They can get professional-grade materials that aren’t available in stores. They know how to get necessary permits and pass inspections.

At Estevez Electric LLC, our licensed electricians provide reliable wire repair services with attention to detail and commitment to safety.

Upgrading Your Electrical System for Better Safety

Sometimes, wire repairs are just a temporary solution to a larger problem. Upgrading your electrical system can provide long-term safety and functionality improvements.

GFCI Outlet Installation

GFCI (Ground Fault Circuit Interrupter) outlets are crucial safety devices that protect against electrical shocks in areas where water is present. These outlets monitor the flow of electricity and quickly shut off power when they detect an imbalance, which could indicate a ground fault.

GFCI technology works by constantly comparing the current flowing on the hot wire against the current returning on the neutral wire. In normal operation, these currents should be exactly equal. If even a small amount of current (as little as 4-6 milliamperes) takes an alternative path—potentially through a person’s body to ground—the GFCI detects this imbalance and trips within a fraction of a second, fast enough to prevent serious injury or electrocution. According to the Consumer Product Safety Commission, GFCI protection has contributed to a 70% reduction in electrocution deaths since their introduction. Modern GFCI outlets include self-testing features that periodically verify their protective functions are working correctly, providing an additional layer of safety assurance.

The National Electrical Code requires GFCI protection in kitchens, bathrooms, garages, basements, and outdoor areas. Upgrading to GFCI outlets in these locations is a relatively simple yet effective safety improvement that can prevent serious injuries.

Surge Protector Installation

Whole-house surge protectors provide comprehensive protection against power surges that can damage wiring and electronics. Unlike plug-in surge protectors that only protect individual devices, whole-house systems protect your entire electrical system.

Whole-house surge protection works on multiple levels to safeguard your electrical system. These devices are typically installed at the main electrical panel and work by diverting excess voltage to ground when they detect voltage levels above normal thresholds. Professional-grade surge protectors are rated by their energy absorption capability, measured in joules, with higher ratings indicating greater protection capacity. Many modern systems include indicator lights that show protection status and alert homeowners when the protective components have been degraded by surge events and need replacement. According to insurance industry studies, homes with whole-house surge protection experience 80% fewer surge-related electrical damages and claims. For comprehensive protection, electrical engineers recommend a layered approach that combines whole-house protection with point-of-use surge protectors for sensitive electronics.

These devices are typically installed at your electrical panel and provide the first line of defense against surges from lightning strikes, utility switching, or large appliances cycling on and off. Professional installation ensures proper connection and maximum protection.

Electrical Panel Upgrades

Upgrading your electrical panel is one of the most significant improvements you can make to your home’s electrical system. Modern homes with multiple electronic devices, appliances, and HVAC systems require more power than older electrical panels can safely provide.

The electrical panel serves as the central distribution point for all power in your home, making it the most critical component of your electrical system. Older homes often have panels rated for just 60 or 100 amps, while contemporary household needs typically require 200 amps or more. Beyond simply increasing capacity, modern panels incorporate advanced circuit breaker technology with more sensitive trip mechanisms that respond faster to dangerous conditions. They also feature better bus bar designs that reduce the risk of arcing and overheating. Panel upgrades often include replacing outdated wiring types like aluminum or knob-and-tube with modern copper wiring, further enhancing safety. Many insurance companies now offer premium discounts for homes with updated electrical panels, recognizing their significant contribution to reducing fire risks.

Signs that you may need a panel upgrade include frequent circuit breaker trips, flickering lights when appliances turn on, or having to unplug one appliance to use another. A modern panel with adequate capacity reduces the risk of overloaded circuits and electrical fires.

Conclusion

Electrical wire repair is a critical aspect of home maintenance that requires careful attention to safety, proper diagnosis, and appropriate intervention. While minor wire repairs can sometimes be handled by knowledgeable homeowners with proper precautions, the complexity and potential dangers of electrical systems make professional expertise essential for most situations. Understanding when to attempt DIY repairs and when to call professionals is perhaps the most important decision a homeowner can make regarding electrical issues.

The causes of electrical wire damage are varied, ranging from physical damage and wear to overloaded circuits, water exposure, and power surges. By recognizing these common causes and their warning signs, homeowners can take proactive measures to prevent wire damage and address issues before they become dangerous. Regular inspection of visible wiring, proper use of electrical outlets, and timely upgrades to outdated systems all contribute to maintaining a safe electrical environment in your home.

Safety must always be the top priority when dealing with electrical systems. The fundamental safety practices of turning off power at the source, verifying that power is off with proper testing equipment, using insulated tools, and knowing your limitations cannot be overstated. These precautions have prevented countless electrical injuries and fatalities over the years, and they remain as important today as ever.

For homeowners who choose to perform basic electrical repairs, having the right tools and understanding proper techniques is essential. However, it’s equally important to recognize that electrical work is governed by complex codes and safety standards that professional electricians spend years learning. The investment in professional electrical services often pays for itself through proper diagnosis, code-compliant repairs, warranty protection, and most importantly, the safety and peace of mind that comes with expert workmanship.

Modern electrical safety features like GFCI outlets, whole-house surge protectors, and updated electrical panels represent significant advances in protecting homes and families from electrical hazards. These upgrades, while requiring professional installation, provide long-term safety benefits that far exceed their initial cost. As our dependence on electrical devices continues to grow, ensuring that our home electrical systems can safely support these demands becomes increasingly important.

At Estevez Electric LLC, we understand that electrical issues can be concerning and disruptive. Our team of licensed electricians is committed to providing safe, reliable, and code-compliant electrical wire repair services. Whether you’re dealing with an emergency situation or planning preventive upgrades, professional electrical services ensure that your home’s electrical system operates safely and efficiently for years to come. Don’t take chances with electrical safety—when in doubt, call the professionals who have the training, experience, and tools to handle electrical repairs safely and effectively.